Introduction to 3D Printing

The world of 3D printing offers endless possibilities, turning digital designs into physical objects. If you’re looking to understand how to use a 3D printer, the first step is grasping the basics of the technology. 3D printing, also known as additive manufacturing, involves layering materials to build an item from a digital file. This cutting-edge process has become more accessible and is revolutionizing various industries. From prototyping to final product manufacturing, the applications are extensive.

As a beginner, you should familiarize yourself with the main types of 3D printing methods. The most common ones include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each technique has its own advantages and specific uses, depending on the desired outcome and the material in use. For instance, FDM is widely used for basic models and prototypes due to its cost-effectiveness and ease of use.

It’s important to note that 3D printing is not just about the printer itself. Understanding the available materials and how they affect the final product is a critical piece of the puzzle. With the right materials and design, what you can create is limited only by your imagination.

As you embark on this journey, remember that practice makes perfect. Start with simple projects and gradually work your way up to more complex prints. Learn from each attempt, and don’t be discouraged by initial failures—they’re stepping stones to your improvement. Embrace the process, and you’ll soon unlock the full potential of 3D printing.

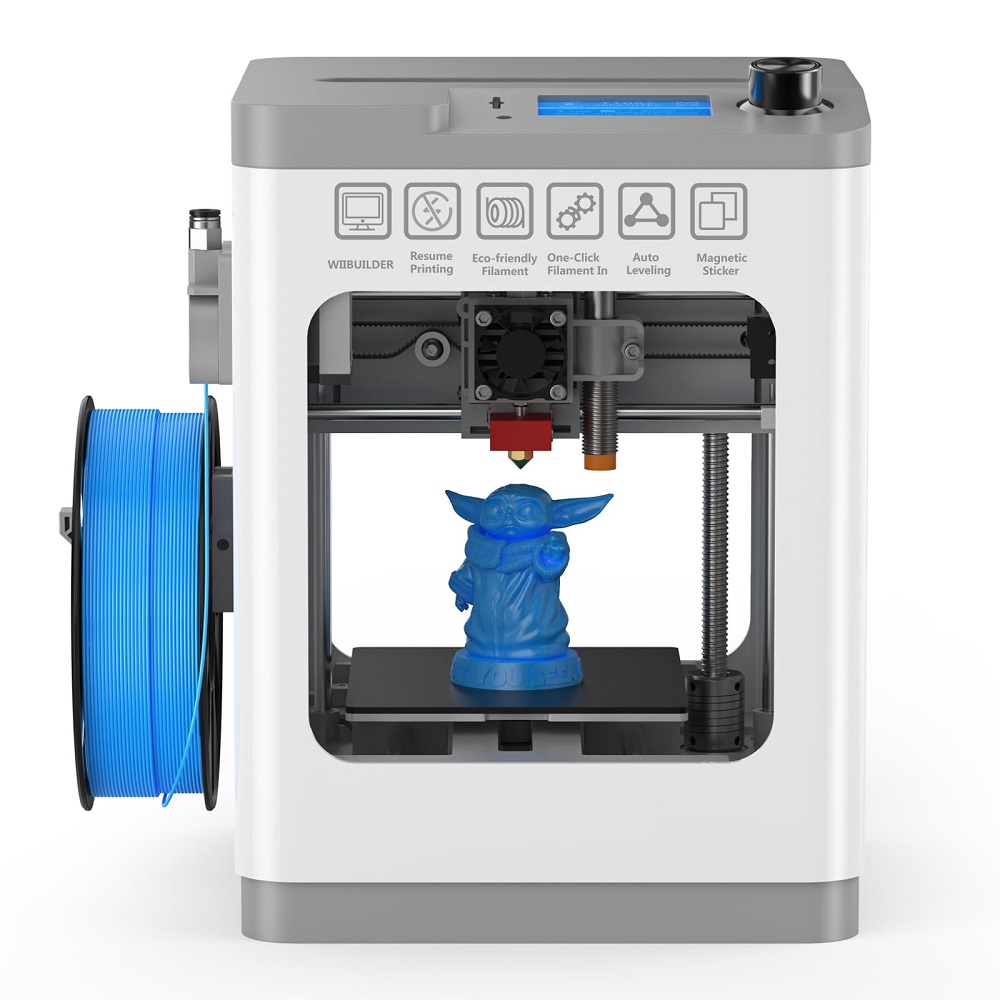

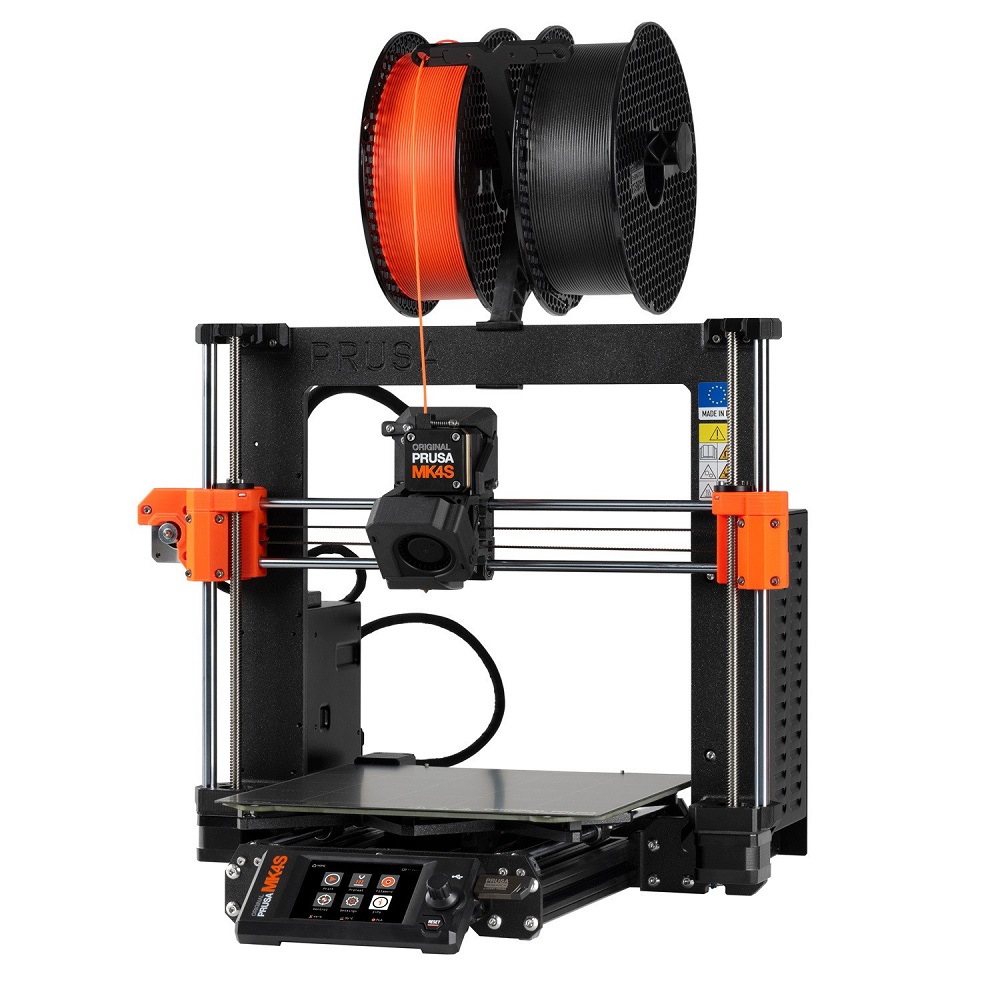

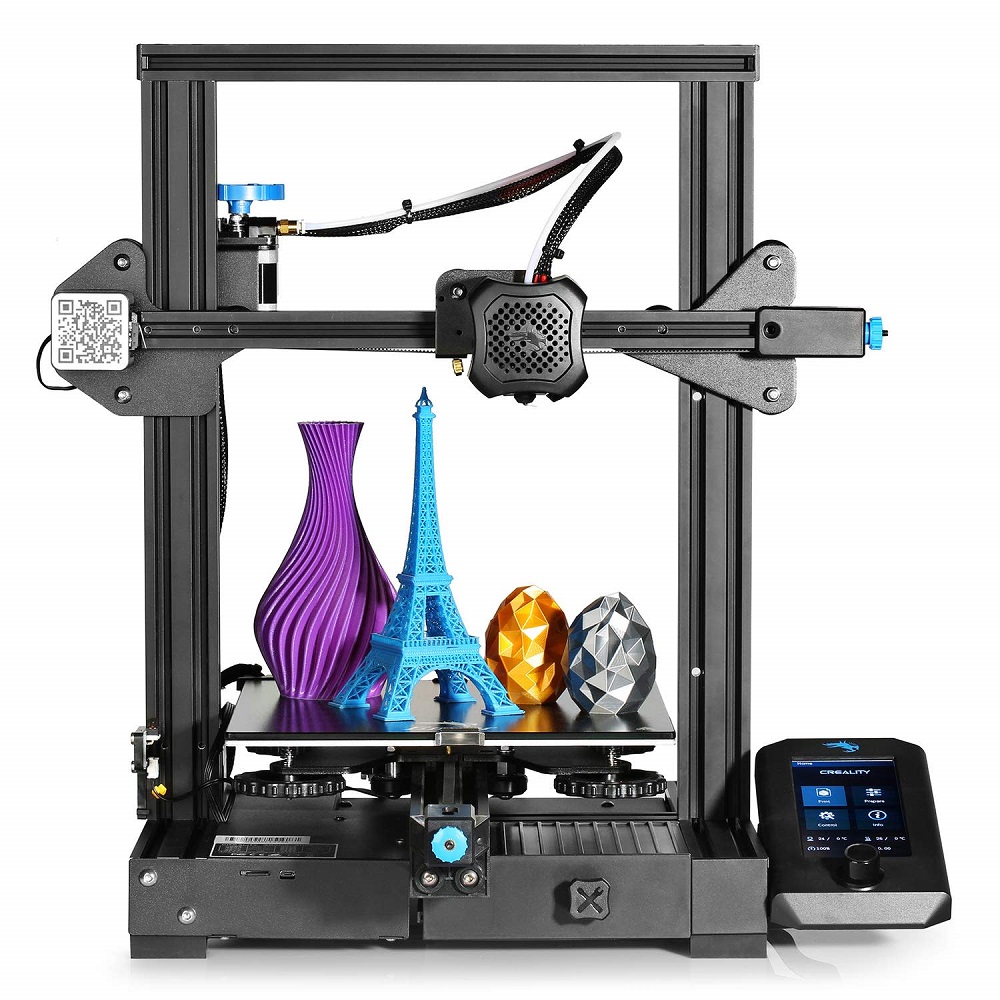

Choosing Your First 3D Printer

When venturing into the world of 3D printing, selecting the right printer is a pivotal decision. As a novice, you might feel overwhelmed by the varied options available. Here are key factors to consider when choosing your first 3D printer.

- Printer Type: Reflect on what you aim to create. Fused Deposition Modeling (FDM) printers are ideal for beginners due to their simplicity and affordability. If you’re interested in intricate details, consider Stereolithography (SLA).

- Print Quality: Examine the printer’s resolution, expressed in microns; lower numbers indicate higher precision. Look for sample prints to gauge the quality.

- Print Size: Think about the maximum size of objects you plan to print. Ensure the printer’s build area can accommodate your projects.

- Material Compatibility: Some printers only work with specific materials. Decide on the materials you are likely to use and check if the printer supports them.

- Ease of Use: User-friendly interfaces, pre-assembled parts, and reliable support can simplify your learning curve.

- Price: Establish your budget. Remember, the initial cost is just one part. Consider ongoing expenses like materials and maintenance.

- Software: Learn what software the printer uses. User-friendly software can enhance your 3D printing experience.

- Community Support: A strong online community for your printer can be an invaluable resource for troubleshooting and learning new tips.

Armed with this knowledge on how to use a 3D printer and what to look for, you are well on your way to starting your 3D printing journey. Remember to read reviews, watch tutorials, and possibly connect with experienced users to make an informed decision.

Understanding 3D Printing Materials

When learning how to use a 3D printer, knowing about materials is key. The material you choose can greatly impact the durability, finish, and function of your printed object. Here’s what you need to consider for your 3D printing projects.

- Material Types: First, learn about the different types of materials. There are plastics like PLA and ABS, resins for SLA printers, and even metals and ceramics for advanced methods. Think about what you want to create, and pick a material that fits both the function and look of your item.

- Material Properties: Each material behaves differently. Some can withstand high temperatures, while others are more flexible or durable. Check the specific properties like strength, flexibility, and heat resistance to find the perfect fit for your print.

- Costs: Materials vary in price. Budget options like PLA are good for practice and simple items. If you need high-quality finishes or strength, you may need to invest more in specialty materials.

- Availability: Some materials are more widely available than others. Make sure you can easily buy the materials you need for your printer, or you might have to adapt your projects accordingly.

- Safety: Consider the safety aspects. Materials can release fumes when printing, so good ventilation is important. Certain materials also require careful handling, such as UV-sensitive resins.

Choosing the right material is just as important as choosing the right 3D printer. Take the time to research and understand the options. This will help ensure successful prints and a satisfying 3D printing experience.

Designing Your First 3D Model

Before you start printing, you need a design. Designing your first 3D model can be thrilling. Here’s a guide to help you create your first design effectively.

Choose the Right Design Software

Select software that suits your skill level. Beginners often find user-friendly programs like TinkerCAD helpful. More experienced users may prefer advanced features of software like Blender or Fusion 360.

Learn Basic Design Principles

Understand 3D design basics like scaling, meshing, and texturing. These are crucial for creating models that are not only good-looking but also printable.

Start with Simple Projects

Begin with simple shapes. Practice making cubes, spheres, or pyramids. This helps you understand how designs translate from software to printed object.

Use Ready-Made Designs

Not ready to design from scratch? Use platforms like Thingiverse to download pre-made models. This can also help you learn by tweaking existing designs.

Think about Printability

While designing, consider the limits of your 3D printer. Avoid overly complex structures that might be difficult to print.

Test and Iterate

Make prototypes of your design. Testing helps you see if the design works and what needs improvement. Iterate based on test results to refine your model.

Mastering design skills takes practice and patience. Keep learning how to use a 3D printer through each design you create.

Preparing Your Model for Printing

Once you have your 3D model ready, preparing it for the 3D printer is the next crucial step. Proper preparation ensures a smoother printing process and increases the likelihood of a successful print. Here are the essential steps to prepare your model for printing.

- Check the Model’s Integrity: Inspect your design for any errors. Look for holes, non-manifold edges, and other flaws that could affect printing.

- Scale to Desired Size: Make sure the model’s size matches what you want the final print to be. Adjust the scale in your design software accordingly.

- Add Supports if Necessary: Some designs with overhangs or complex features might need support structures. Add these in the slicing software to ensure the model prints correctly.

- Slice Your Model: Use slicing software to convert your 3D model into a format your printer can understand. This software will also let you adjust print settings like layer height and print speed.

- Choose Layer Height: A lower layer height can result in finer detail, but it will increase print time. Choose the right balance for your project’s needs.

- Select Print Speed: A slower print speed can improve print quality but takes longer. Find the right speed for your model and printer capabilities.

- Preview the Print Path: Many slicers allow you to preview the print path. Check it to anticipate any potential issues during the actual print.

Each of these steps is key to understanding how to use a 3D printer effectively. With your model prepared correctly, you can look forward to an exciting and rewarding printing experience.

3D Printing Process Explained

Once you have chosen your printer, materials, and have your model designed and prepped, it’s time to dive into the 3D printing process itself. This is where your digital design becomes a tangible object. Understanding this process is crucial for successful prints. Here’s a step-by-step guide on how to use a 3D printer during the actual printing phase.

- Step 1: Load Your Material: Start by loading the material, such as PLA or ABS plastic, into the printer. Ensure that the filament is properly fed to the extruder.

- Step 2: Set Up the Print Bed: Prepare the print bed, which may involve applying an adhesive or calibrating the bed level. This helps the first layer stick properly.

- Step 3: Begin Printing: Once set up, start the print job. The printer will heat the material and begin laying it down layer by layer according to your design.

- Step 4: Monitor the Print: Keep an eye on the printing process. Watch for issues like warping or misprints. Prompt intervention can save a print from failure.

- Step 5: Remove the Print: After the print job is complete, carefully remove the object from the print bed. It might be hot, so take precaution.

- Step 6: Post-Processing: Some prints may need sanding, painting or assembling additional parts. This is referred to as post-processing and will be covered in the next section.

Remember, 3D printing is often a trial-and-error process. Each print can teach you how to better use your 3D printer, refine your technique, and produce higher quality prints.

Post-Processing Your 3D Prints

After your 3D print is complete, post-processing can enhance its appearance and functionality. This step transforms a rough print into a polished final product. Here’s what to do for post-processing.

- Trimming and Sanding: Remove any excess material or support structures. Use fine grit sandpaper to smooth out the surface.

- Painting: If desired, apply paint to your print. Use a primer first for better paint adhesion.

- Gluing: Some prints come out in parts. Use strong adhesive to assemble them.

- Sealing: Apply a sealant to protect the print, especially if it’s going to be handled often

- Testing: Make sure moving parts work smoothly. Check if the print fits its intended place or purpose.

Each of these techniques requires patience and a careful hand. Take your time to achieve the best results. With practice, your post-processing skills will greatly improve. This can make all the difference in bringing your 3D creations to life.

Common 3D Printing Problems and Solutions

As you learn how to use a 3D printer, you will face challenges. Common issues include print not sticking, warping, and poor quality details. Knowing how to solve these can save time and frustration.

- Print Not Sticking: If prints don’t stick to the bed, check bed level and temperature. Clean the bed and apply adhesive like glue or tape.

- Warping: For warping, make sure the printing environment has stable temperature. Use a heated bed and consider brims or rafts to anchor the print.

- Poor Quality Detail: When details are not sharp, adjust the printer’s resolution. Slow down the print speed and make sure the material is dry.

- Nozzle Clogs: If the nozzle clogs, try cleaning it with a needle. Also, check for the correct temperature for your material to prevent clogs.

- Layer Shifting: Layer shifting might happen due to loose belts. Tighten the belts and ensure the printer is on a stable surface.

- Stringing: Reduce stringing by tweaking retraction settings. Increase travel speed and lower the printing temperature slightly.

These are just a few common problems with easy-to-apply solutions. Keeping a troubleshooting checklist can be helpful. You will get better with each problem you solve. Stay patient and keep experimenting with settings and materials.

Maintaining Your 3D Printer

Maintaining your 3D printer is crucial for ensuring its longevity and performance. Regular upkeep helps avoid common issues that can arise during printing sessions. Here are some essential maintenance strategies to practice.

- Clean Regularly: Dust and debris can accumulate and affect your printer’s function. Clean the printer’s exterior and the print bed after each use.

- Lubricate the Moving Parts: Apply lubricant to the rails and rods periodically. This reduces wear and tear and ensures smooth operation.

- Update Firmware and Software: Keep your 3D printer’s software and firmware up to date. Updates often fix bugs and improve performance.

- Check for Wear and Tear: Inspect belts, nozzles, and other components for signs of wear. Replace parts as necessary to avoid breakdowns.

- Calibrate the Printer: Regularly calibrate your printer to ensure precision in your prints. Check the alignment and level the print bed.

- Store Materials Properly: Keep filaments and other materials in a dry, cool place. Proper storage prevents material degradation, which can affect print quality.

Following these steps will help you maintain optimal performance and extend the life of your 3D printer. Regular maintenance not only improves print quality but also saves money on potential repairs.

Resources and Communities for 3D Printing Enthusiasts

Entering the 3D printing world can feel complex and daunting. Fortunately, numerous resources and communities exist to guide and support you along the way. Here, we discuss some of the most beneficial platforms you can tap into as you learn how to use a 3D printer.

- Online Forums and Message Boards: These are gold mines for information. Popular sites like Reddit’s r/3Dprinting and the RepRap Forum are bustling with fellow enthusiasts.

- Social Media Groups: Facebook and LinkedIn host multiple groups where you can ask questions, share your work, and connect with others.

- YouTube Channels: Plenty of experts share their knowledge on YouTube. Watch tutorials, reviews, and guides to improve your skills.

- Maker Spaces: Joining a local maker space can be invaluable. They offer not just equipment but also workshops and a community of experienced members.

- 3D Printing Websites: Websites like Thingiverse and MyMiniFactory offer a vast array of downloadable designs. They also have forums for discussion and advice.

- Manufacturers’ Support: Don’t overlook the support from your printer’s manufacturer. They often provide detailed guides and customer support.

Remember, tapping into communities helps with troubleshooting, provides inspiration, and keeps you updated on the latest 3D printing trends.

Leave a Reply