Overview of Wireless Printing Technology

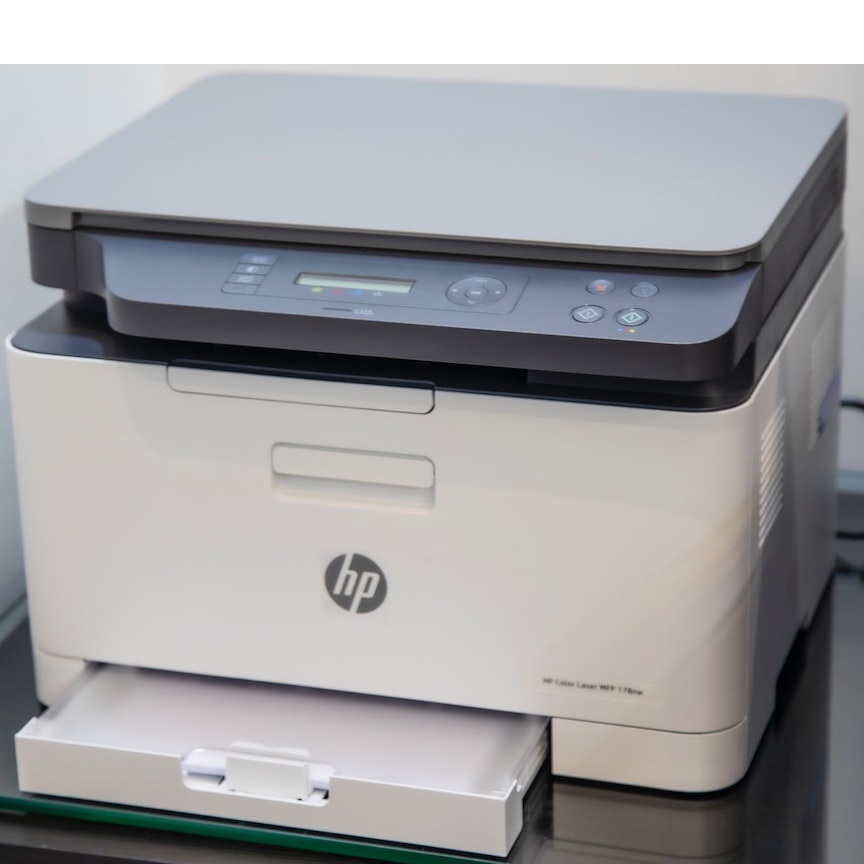

Wireless printing has revolutionized how we send documents and images to print. It allows users to print without the need for physical cables. This technology uses radio waves to connect devices like smartphones, tablets, and laptops to your HP printer. In recent years, wireless printing has become more reliable and faster. Wireless standards such as Wi-Fi Direct and Bluetooth are common in modern HP printers. These standards help in connecting HP printer to WiFi with ease.

For users, the benefits of wireless printing are clear. It offers the convenience of printing from anywhere within the network range. Also, it supports multiple devices. Most importantly, it reduces clutter and the hassle of dealing with numerous cables. For HP printers specifically, the integration of wireless technology has led to smart, efficient, and user-friendly printing solutions. These printers often come with dedicated apps for easy setup and use.

Connecting your HP printer to WiFi involves a few simple steps. First, you must ensure your printer is WiFi capable. Then, you need a stable wireless network. Finally, you must follow the specific instructions for your HP printer model to establish the connection. Once set up, you can enjoy the freedom of printing from various devices. And you can do this without being tied to one location.

This advancement not only adds to your convenience but also paves the way for future innovations in printing technology. With each passing year, we are moving towards more integrated and intelligent systems. These systems aim to improve the quality and accessibility of printing.

Benefits of WiFi-Enabled HP Printers

WiFi-enabled HP printers provide numerous advantages that significantly enhance your printing experience. Here’s why choosing a WiFi-enabled HP printer is a great decision:

- Remote Printing: Print from anywhere in your home or office, as long as you’re connected to the same network. This flexibility allows you to be productive without being restricted to a desk.

- Reduced Clutter: Without the need for physical cables, your workspace remains neat. This leads to a more organized and less cluttered environment.

- Easy Setup and Maintenance: Connecting HP printer to WiFi is straightforward. With the guided setup process, you can start printing in no time. Maintenance also becomes easier with wireless technology.

- Multi-Device Compatibility: Connect multiple devices without needing multiple cables. Whether you’re using a smartphone, tablet, or laptop, you can easily send print jobs to your HP printer.

- Enhanced Features: Many WiFi-enabled HP printers come with additional features. These include cloud printing services, the ability to print directly from social media, and access to printer apps that simplify the printing process.

By choosing a WiFi-enabled HP printer, you are not only investing in a quality device but also in a smoother, more-efficient printing process. This choice will serve you well in both your personal and work life.

Preparing to Connect: What You Need

Before you start connecting your HP printer to WiFi, ensure you have all necessary equipment and information. Here’s a checklist:

- WiFi-Enabled HP Printer: Confirm that your HP printer supports WiFi connectivity.

- Active Wireless Network: An active and stable WiFi network is crucial. Know your network’s name (SSID) and password.

- Computer or Mobile Device: You need a device, like a laptop or smartphone, to set up the connection.

- Printer Software or App: Install the latest version of HP printer software or app on your device for easy setup.

- Power Source: Ensure your printer is plugged in and turned on.

Gathering these items beforehand will streamline the process of connecting your HP printer to WiFi.

Step-by-Step Instructions for Connecting HP Printer to WiFi

Connecting your HP printer to your home or office WiFi network is a simple process. Just follow these easy steps:

- Turn on Your HP Printer: Make sure your printer is on and ready.

- Access Printer’s Control Panel: Navigate to the printer’s built-in menu or touch screen display.

- Select Network Options: Look for a networking or wireless settings option.

- Choose ‘Wireless Setup Wizard’: This wizard will guide you through the connection process.

- Select Your WiFi Network: Find and select your network’s SSID from the list shown.

- Enter Password: Carefully type in your WiFi password using the printer’s interface.

- Confirm Settings: Check the details you entered and confirm to connect your printer.

- Print a Test Page: Ensure your setup was successful by printing something.

If your printer has a WPS button, you may also use it for a quick setup. Just press the WPS button on your printer and router. This automatically connects your HP printer to WiFi without entering details.

By completing these steps, you can start enjoying remote printing from various devices. It’s fast, efficient, and gives you the freedom to print from anywhere within the network’s range.

Troubleshooting Common Connection Issues

Even with user-friendly HP printers, you might face issues while connecting to WiFi. Here is how to troubleshoot common problems:

- Printer Not Found: Ensure that your printer is on and its wireless feature is active. Restart your HP printer and try the setup process again.

- Incorrect Password Error: Double-check that you entered the right WiFi password. Remember that passwords are case-sensitive.

- WiFi Network Not Listed: Place your printer closer to your router. This improves the signal strength and may make your network appear.

- Connection Drops: Test your WiFi signal strength. Other devices might work well even with a weak signal, but your printer might need more strength to maintain the connection.

- Printer Offline Error: Check the printer’s status in your computer’s settings. If it’s offline, try a reboot of both your printer and router, and attempt to reconnect.

- Outdated Printer Firmware: Update your printer firmware to the latest version. Outdated software can cause connection problems.

If you follow these tips and still can’t connect your HP printer to WiFi, HP’s customer support can help. They offer guidance and troubleshoot any complex issues you may encounter.

Advanced Features and Security Settings for HP WiFi Printers

Today’s HP WiFi printers boast not just convenience and connectivity, but also a range of advanced features that greatly enhance user experience. These sophisticated functions have been designed to meet the increasing needs for efficiency and safety in both personal and professional environments.

- Touchscreen Displays: Many HP WiFi printers come with intuitive touchscreen panels. They make navigating through different settings and functions simple.

- Voice-Activated Printing: Some models feature voice recognition abilities. You can use commands to print documents hands-free.

- Remote Printing Capabilities: With HP’s ePrint technology, you can print from anywhere in the world. Email the document to your printer’s email address and it prints immediately.

- Automatic Updates: To keep your printer secure, HP WiFi printers often update themselves over the network. This feature ensures that your device remains protected against the latest threats.

Security is a major concern in wireless technology. HP WiFi printers address this issue by offering several robust security settings to protect your data.

- Password Protection: Secure your printer’s access through a strong password to prevent unauthorized use.

- Network Encryption: Utilize standard network encryption protocols. They protect information as it’s sent to and from the printer across the WiFi network.

- Secure Boot and Secure Code Signing: These features prevent malicious codes from compromising printer firmware.

- Firewall Protection: Manage network traffic and prevent potential attacks with built-in firewall options.

By utilizing these advanced features and security measures, you can enjoy safe and cutting-edge printing technology. Integrating an HP WiFi printer into your workflow simplifies tasks and secures your information. Ensure you keep your printer’s firmware and software updated to maintain optimal performance and security.

Tips for Maintaining a Stable Connection

Keeping your HP printer reliably connected to WiFi is crucial for seamless printing. Here are simple tips you can follow:

- Check Printer Location: Place your HP printer close to the router. This ensures a stronger signal.

- Avoid Interference: Keep your printer away from devices that can cause interference, like microwaves and cordless phones.

- Regular Updates: Always keep your printer’s software up to date. Updates can improve connectivity.

- Reboot Regularly: Turn off your printer and router once in a while. Then turn them back on. This can refresh the connection.

- Use a Static IP Address: Assign a static IP to your printer. It helps avoid IP conflicts on your network.

- Check Bandwidth Usage: Ensure other devices aren’t hogging the bandwidth when you’re printing.

- Quality Router: Invest in a good quality router. A good router can provide a stable and strong WiFi signal.

- Network Security: Secure your network with a strong password to prevent unauthorized access.

By following these tips, you can help prevent common connectivity problems. Your HP printer will be more likely to maintain a stable WiFi connection.

Future of Printing: Innovations and Trends

The future of printing, especially related to HP printers, is poised for substantial breakthroughs. As wireless technologies evolve, there will be significant innovations that enhance connectivity and functionality.

- Integration of AI: Artificial Intelligence (AI) is set to redefine how printers operate. AI could automate many tasks such as ink level detection and troubleshooting.

- Sustainable Printing Solutions: Eco-friendly printing will become more prevalent. We can anticipate more HP printers designed to use less energy and ink. Manufacturers will likely use recycled materials for printer build.

- Enhanced Security Features: As cyber threats increase, the security in HP WiFi printers will strengthen. Expect robust measures to shield against data breaches.

- 3D Printing Technology: HP might expand into more advanced 3D printing solutions, making this technology accessible for home use.

- Cloud-Based Printing: The shift to cloud computing will continue to influence HP printers, allowing for seamless remote operations and storage.

- Edge Computing: This will push data processing to the printer’s edge, reducing latency, and increasing processing speed.

These innovations not only suggest more sophisticated HP printer capabilities but also a commitment to user-friendly and secure printing options. Future trends aim to balance high performance with sustainability and security.